Common Freeze-Drying Mistakes

Common Freeze-Drying Mistakes

In the world of freeze-drying, as in any skill, making mistakes is part of the learning process. Many enthusiasts have faced challenges and shared their valuable experiences in online communities and forums, offering insights into overcoming common pitfalls.

To help you navigate your freeze-drying journey with confidence, we've compiled a list of mistakes to avoid.

By sidestepping these errors, you can ensure smoother and more successful freeze-drying adventures. Common Freeze-Drying Mistakes

Neglecting Regular Cleaning

Mistake: Not cleaning the freeze-dryer often enough.

Solution:

Maintaining a clean machine is vital for optimal performance and the longevity of your freeze-dryer. Although you don't need to clean it after every use, establishing a routine for regular cleaning is essential. Use a soft cloth and warm water to clean both the interior and exterior of the machine.

Avoid abrasive cleaners, brushes, or pads that could damage the surface. If you notice lingering odors after processing a batch, use a solution of water and either isopropyl alcohol or Everclear to wipe down the interior and shelving unit. Always dry the machine with a soft cloth after cleaning.

Don't forget to periodically clean the drain hose by closing the drain valve and pouring alcohol or soapy water down the hose, letting it sit for 20 minutes to sanitize the drain line.

Common Freeze-Drying Mistakes

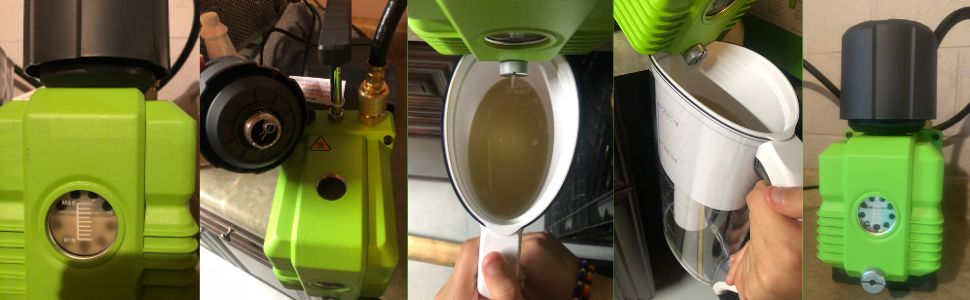

Skipping Oil Changes

Mistake: Not performing regular oil changes for the vacuum pump.

Solution:

Changing your pump's oil on schedule is crucial to ensure it remains in excellent working condition. Before starting each new batch, check the pump's indicator window to gauge the oil level. If the oil appears cloudy or contains food particles, it's time for an oil change.

Be sure to follow the manufacturer's recommendations regarding the frequency of oil changes to maintain a smoothly running pump.

Common Freeze-Drying Mistakes

Freeze-Drying Food That's Too Thick or Heavy

Mistake: Processing food that is excessively thick or heavy.

Solution:

While it might be tempting to expedite the process by slicing food into thick pieces, doing so can impact the quality of your freeze-dried goods. Food that's too thick can lead to shorter shelf life and strain on your machine. It's crucial to prep your food to the correct thickness before placing it in the freeze-dryer.

Aim for slices that are no thicker than ½" (with an absolute maximum of ¾"), liquids up to ½" deep, and chunks up to ¾" in size.

Skipping Pre-Freezing

Mistake: Neglecting to pre-freeze food before starting the freeze-drying process.

Solution:

One of the primary reasons for freeze-drying mishaps is failing to pre-freeze food completely. Pre-freezing ensures that the food is fully solid when the pump activates, preventing explosions and reducing stress on your machine.

Always pre-freeze your food for 24 to 48 hours to ensure it's rock-solid.

While a few foods with exceptionally low water content, like herb leaves or shredded cheese, can be freeze-dried without pre-freezing, it's a best practice to pre-freeze most items.

Skipping a Dry Check

Mistake: Failing to perform a dry check after processing a batch.

Solution:

It's essential to confirm that your freeze-dried food is thoroughly dry before packaging it for long-term storage. While there are various methods to check for doneness, one of the most reliable approaches is by measuring the weight. After your food has gone through Extra Dry Time, record its weight. Then, return the trays to the machine for an additional four hours of extra dry time and check it again at the two-hour mark.

If the weight remains consistent, your food is dry. If it has changed, continue drying until the weight stabilizes. Remember, you can't over-dry food, so it's better to err on the side of caution.

Neglecting Oxygen Absorbers

Mistake: Storing freeze-dried food without oxygen absorbers.

Solution:

Once the freeze-drying process is complete, it's crucial to package the food promptly to prevent moisture reabsorption from the air. Maintain low humidity in the storage room using a dehumidifier or air conditioner if necessary. After placing the food in jars or bags, open the oxygen absorbers, remove the required number, and reseal the package (using dial level 5).

Place the oxygen absorbers inside the packaging and seal the containers. Don't worry if some nitrogen remains in the bag; the critical objective is to remove oxygen.

Use 100cc absorbers for quart jars and 300cc absorbers for gallon Mylar bags.

Ignoring Recommended Foods

Mistake: Not adhering to the recommended foods for freeze-drying.

Solution:

Using the wrong foods in your freeze-dryer isn’t just messy — it can ruin batches, shorten shelf life, and damage your machine. Oily, fatty, and high-sugar foods (like peanut butter, honey, and syrups) often go rancid or cause explosions inside the chamber. Stick to proven ingredients for long-term preservation — and save the experiments for short-term snacks or camping meals.

“Foods that should not be freeze-dried will either go rancid, explode into a mess, or have decreased shelf life. Avoiding items high in fat or sugar will keep your food fresh and safe to eat for a longer amount of time”. - The Only Beginner Freeze Drying Book You'll Ever Need.

Additional Resources

You can access the Customer Support troubleshooting wizard on the Harvest RightTM website by visiting FDHR.2MHE.COM, located in the upper right-hand corner.

This resource can provide further assistance in addressing any freeze-drying challenges you may encounter.

Remember, every mistake is an opportunity to learn and improve.

By avoiding these common pitfalls and utilizing available resources, you'll enhance your freeze-drying skills and enjoy delicious, long-lasting results.

Happy freeze-drying!